Cuplock Scaffolding For Industrial Maintenance: Key Benefits

Industrial maintenance is a critical operation in various industries to ensure the smooth functioning of equipment and machinery. In these settings, the use of scaffolding is essential to provide a safe and secure working environment for maintenance personnel. Cuplock scaffolding is one such versatile system that offers several key benefits for industrial maintenance tasks. In this article, we will explore the advantages of using Cuplock scaffolding in industrial maintenance operations.

Enhanced Safety and Stability

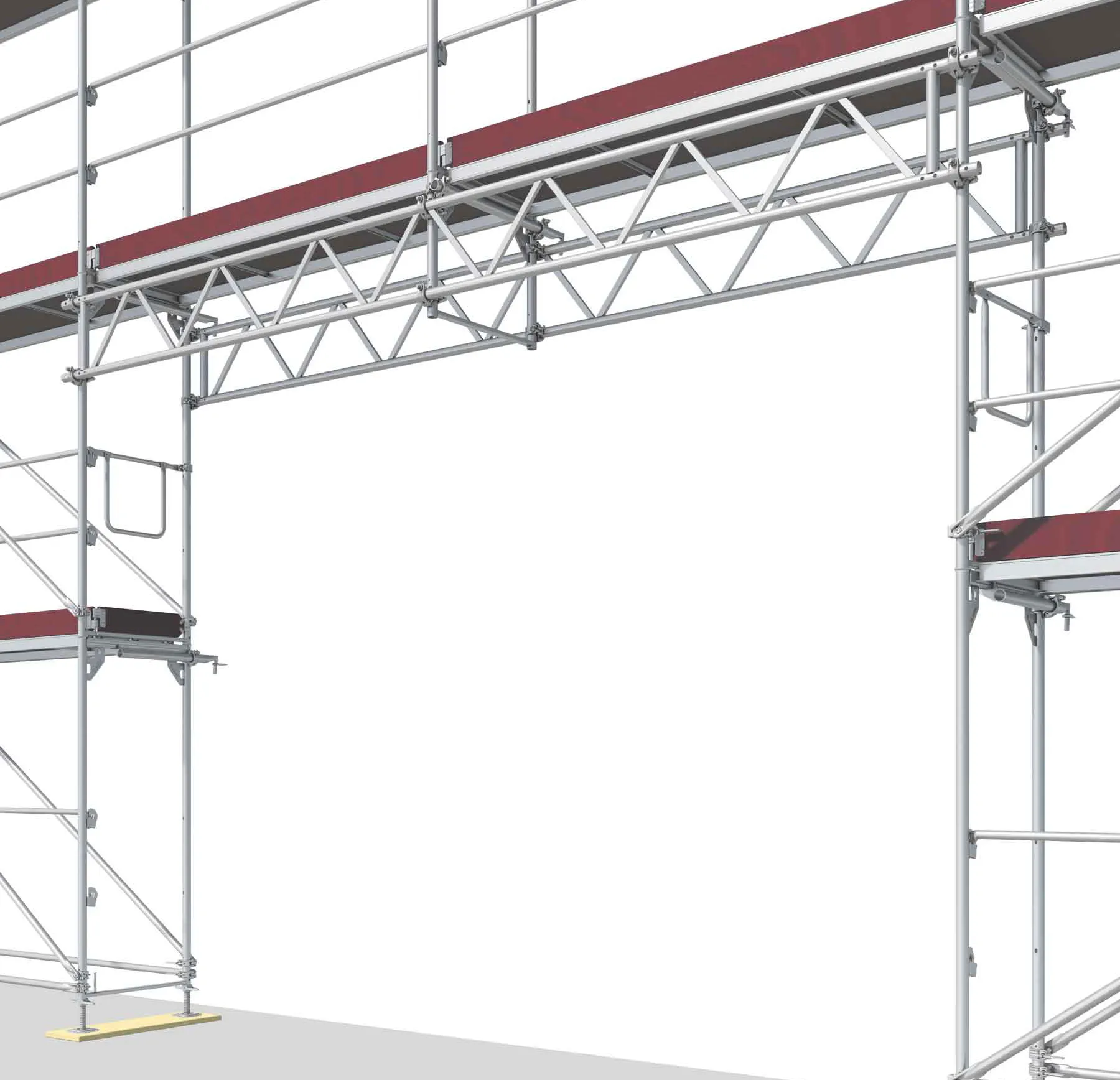

Cuplock scaffolding is renowned for its robust design, which provides enhanced safety and stability for workers performing maintenance tasks at height. The unique node point connection system of Cuplock scaffolding ensures a secure and rigid structure that can withstand heavy loads and adverse weather conditions. This stability is crucial in industrial maintenance settings where workers need to work on complex structures and machinery. With Cuplock scaffolding, workers can have peace of mind knowing that they are working on a safe and reliable platform.

Moreover, the 'no loose fittings' feature of Cuplock scaffolding eliminates the risk of components coming apart during use, further enhancing safety on site. This attribute is particularly important in industrial maintenance, where any structural failure can have severe consequences. By choosing Cuplock scaffolding, companies can prioritize worker safety and minimize the risk of accidents during maintenance operations.

Speed and Efficiency

Another key benefit of using Cuplock scaffolding in industrial maintenance is its speed and efficiency. The unique locking mechanism of Cuplock scaffolding allows for quick and easy assembly, significantly reducing construction time compared to traditional scaffolding systems. In industrial maintenance settings where time is of the essence, this efficiency can lead to cost savings and increased productivity.

The modular design of Cuplock scaffolding also contributes to its speed and efficiency. The system comprises standard verticals with captive mobile top cups and captive ledger blades, allowing for flexible configurations to suit different maintenance requirements. This modularity enables workers to adapt the scaffolding to various structures and spaces quickly, minimizing downtime and maximizing work progress. By utilizing Cuplock scaffolding, industrial maintenance teams can complete tasks more efficiently, leading to improved maintenance schedules and overall project timelines.

Versatility and Adaptability

Cuplock scaffolding is highly versatile and adaptable, making it suitable for a wide range of industrial maintenance applications. The system's standard components can be easily reconfigured and combined to create customized scaffolding solutions for various maintenance tasks. This flexibility is invaluable in industrial maintenance settings where structures and equipment often have unique shapes and dimensions that require tailored access platforms.

Furthermore, Cuplock scaffolding can be erected in both vertical and horizontal orientations, making it ideal for accessing hard-to-reach areas during maintenance operations. The system's ability to accommodate different angles and heights provides versatility in navigating complex industrial environments, ensuring that maintenance personnel can access all areas safely and efficiently. Whether working on pipelines, reactors, or machinery, Cuplock scaffolding offers the adaptability needed to tackle diverse maintenance challenges effectively.

Durability and Longevity

Durability is a crucial factor in scaffolding systems used for industrial maintenance, where structures must withstand heavy loads and harsh working conditions. Cuplock scaffolding stands out for its durability and longevity, thanks to its high-quality materials and robust construction. The hot-dip galvanized finish of Cuplock scaffolding components protects against corrosion and rust, ensuring a long service life even in demanding industrial environments.

The welded node point connections of Cuplock scaffolding further enhance its durability by providing a solid and secure platform for workers. This structural integrity prevents deformation and shifting during use, maintaining the stability and safety of the scaffolding system over time. By investing in Cuplock scaffolding for industrial maintenance, companies can benefit from a long-lasting solution that can withstand the rigors of daily use and provide reliable support for maintenance activities.

Cost-Effective Solution

In industrial maintenance operations, cost-effectiveness is a key consideration when choosing scaffolding systems. Cuplock scaffolding offers a cost-effective solution for companies looking to optimize their maintenance budgets without compromising on safety or quality. The system's quick assembly and dismantle capabilities reduce labor costs associated with scaffolding erection and dismantling, saving time and manpower on site.

Moreover, the reusability of Cuplock scaffolding components contributes to cost savings in the long run. The durable materials and construction of the system allow for multiple applications and reconfigurations, extending its service life and eliminating the need for frequent replacements. By choosing Cuplock scaffolding, companies can benefit from a cost-effective solution that provides consistent performance and reliability for industrial maintenance tasks.

In conclusion, Cuplock scaffolding offers several key benefits for industrial maintenance operations, including enhanced safety and stability, speed and efficiency, versatility and adaptability, durability and longevity, and cost-effectiveness. By choosing Cuplock scaffolding for maintenance tasks, companies can prioritize worker safety, improve efficiency, adapt to various working environments, ensure long-term durability, and optimize maintenance budgets. With its robust design, quick assembly, flexibility, durability, and cost-effectiveness, Cuplock scaffolding proves to be a valuable asset for industrial maintenance projects. Consider incorporating Cuplock scaffolding into your maintenance practices to experience these benefits firsthand.