Unlocking The Benefits Of Cuplock Scaffolding: The Ultimate Guide

Are you looking for a reliable and versatile scaffolding system for your construction projects? Look no further than Cuplock Scaffolding. In this Ultimate Guide, we will explore the numerous benefits and advantages of utilizing Cuplock Scaffolding, from its easy assembly and versatility to its cost-effectiveness and safety features. Whether you're a seasoned contractor or a novice DIY enthusiast, this comprehensive guide will help you unlock the full potential of Cuplock Scaffolding for your next project. Let's dive in and discover why Cuplock Scaffolding is the ultimate choice for all your construction needs.

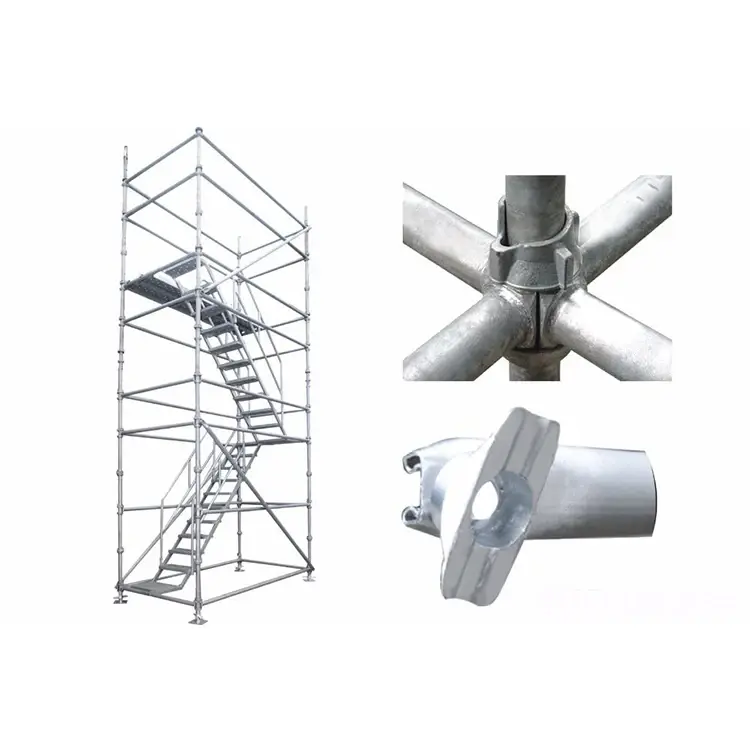

Understanding the Basics of Cuplock Scaffolding

Cuplock scaffolding is a popular type of modular scaffolding system that is widely used in the construction industry. It is known for its versatility, durability, and ease of use, making it a preferred choice for a wide range of construction projects. Understanding the basics of cuplock scaffolding is essential for anyone involved in construction, whether as a contractor, engineer, or worker.

One of the key features of cuplock scaffolding is its unique node point, which allows for up to four horizontal members to be connected to a vertical member in one single action, providing a fast and efficient means of assembly. This makes cuplock scaffolding a highly efficient and time-saving option for construction projects of all sizes.

Another important aspect to understand about cuplock scaffolding is its load-bearing capacity. The design of the cuplock system provides high load-bearing capacity, making it suitable for supporting heavy materials and equipment on construction sites. This makes it a reliable and safe choice for construction projects where strength and stability are essential.

In addition to its strong and durable design, cuplock scaffolding is also highly adaptable and can be easily adjusted to suit the specific requirements of different construction projects. The unique locking mechanism of the cups and ledgers allows for flexible and secure configurations, making it possible to create various shapes and sizes of scaffolding to fit the exact specifications of the building or structure being constructed.

Furthermore, the modular nature of cuplock scaffolding makes it easy to transport and assemble, reducing the overall time and labor required for setting up and dismantling scaffolding on construction sites. This not only saves time and money but also increases the overall efficiency of the construction process.

In terms of safety, cuplock scaffolding is designed with built-in safety features, including captive wedge locks and a unique cuplock node point design, which help to prevent accidental disassembly or slippage. This provides peace of mind for workers and ensures a secure and stable working platform for all construction tasks.

Overall, understanding the basics of cuplock scaffolding is essential for anyone in the construction industry. Its unique design, high load-bearing capacity, versatility, and safety features make it a highly practical and reliable choice for a wide range of construction projects. Whether used for new construction, renovation, or maintenance projects, cuplock scaffolding is a valuable asset that can greatly enhance the efficiency, safety, and success of any construction endeavor.

Advantages of Using Cuplock Scaffolding for Construction Projects

Cuplock scaffolding is a revolutionary system that has quickly become the preferred choice for construction projects around the world. Its innovative design and numerous advantages make it the ultimate choice for contractors and construction companies. In this comprehensive guide, we will explore the many benefits of using cuplock scaffolding for construction projects.

1. Versatility: One of the key advantages of cuplock scaffolding is its versatility. It can be used for a wide range of applications, including both straight and curved structures. This versatility makes it the perfect choice for construction projects of all shapes and sizes.

2. Speed and Efficiency: Cuplock scaffolding is designed for quick and easy assembly, allowing for a faster construction process. The unique node point allows for up to four horizontals to be connected to a vertical at one time, resulting in a significant increase in productivity. This not only saves time but also reduces labor costs, making it a cost-effective option for construction projects.

3. Strength and Durability: Cuplock scaffolding is renowned for its exceptional strength and durability. The robust design can withstand heavy loads, making it suitable for even the most challenging construction projects. The hot-dip galvanized finish provides protection against rust and corrosion, ensuring the scaffolding remains in peak condition for years to come.

4. Safety: Safety is a top priority in the construction industry, and cuplock scaffolding is designed with this in mind. The secure and stable connection system reduces the risk of accidents and provides a safe working environment for construction workers. Additionally, the non-slip surface and secure access points further enhance safety on the job site.

5. Cost-Effectiveness: Cuplock scaffolding offers excellent value for money, making it a cost-effective option for construction projects. The quick assembly and disassembly process result in reduced labor costs, while the durability of the system leads to long-term savings on maintenance and replacement. Its versatility also means that fewer components are required, further reducing costs.

6. Adaptability: Cuplock scaffolding can be adapted to suit various construction requirements, including support for formwork and access scaffolding. The modular design allows for easy customization, making it a flexible option for a wide range of construction projects.

7. Sustainability: As sustainability becomes an increasingly important consideration in the construction industry, cuplock scaffolding stands out as an environmentally friendly option. The long lifespan and recyclability of the system make it a sustainable choice for construction projects.

In conclusion, cuplock scaffolding offers a wide range of benefits that make it the ultimate choice for construction projects. Its versatility, speed and efficiency, strength and durability, safety, cost-effectiveness, adaptability, and sustainability make it a superior option for contractors and construction companies. With its numerous advantages, it is clear that cuplock scaffolding is a game-changer in the construction industry.

How to Properly Assemble and Dismantle Cuplock Scaffolding

Cuplock scaffolding is a versatile and popular system for construction projects of all sizes. Its quick and easy assembly and dismantling make it a preferred choice for contractors and builders. In this ultimate guide, we will walk you through the proper way to assemble and dismantle cuplock scaffolding, ensuring a safe and efficient construction process.

Assembling cuplock scaffolding requires precision and attention to detail. Start by laying out the base of the scaffolding, ensuring it is on a level surface and securely anchored. Then, insert the first standard (vertical tube) into the cuplock bottom cups, followed by the corresponding ledger (horizontal tube) into the top cups. Make sure the connections are tight and secure before adding further standards and ledgers to build the required height and width.

One of the key benefits of cuplock scaffolding is its unique locking mechanism, which allows for easy and secure connections without the need for extra tools or fittings. The cups are designed to fit together seamlessly, providing a stable and strong foundation for the scaffolding structure. As you continue to add standards and ledgers, the cuplock system allows for quick and efficient assembly, saving valuable time on the construction site.

When it comes to dismantling cuplock scaffolding, proper procedures must be followed to ensure the safety of workers and the integrity of the equipment. Start by removing the topmost ledger and then the standards, working your way down to the base. As each component is removed, take care to stack and store them in an organized manner, ready for future use.

It is important to inspect each component for any signs of damage or wear and tear before reassembling the scaffolding. This step is crucial for maintaining the safety and stability of the structure. Any damaged or compromised parts should be replaced immediately to prevent accidents or structural failures.

As with any construction equipment, proper training and supervision are essential when working with cuplock scaffolding. All workers should be well-versed in the assembly and dismantling process, as well as the safety guidelines for working at heights. Additionally, regular maintenance and inspection of the scaffolding components are necessary to ensure their continued reliability and performance.

In conclusion, cuplock scaffolding offers a range of benefits, from its quick and easy assembly to its robust and secure design. By following the proper procedures for assembly and dismantling, contractors and builders can take full advantage of these benefits while ensuring the safety and efficiency of their construction projects. With the right training and attention to detail, cuplock scaffolding can be a valuable asset for any construction site.

Safety Considerations and Best Practices for Working with Cuplock Scaffolding

When it comes to construction and maintenance projects, the safety of workers is of utmost importance. This holds true for any type of scaffolding system that is being used on a job site. Among the various types of scaffolding available, Cuplock scaffolding is a popular choice due to its ease of use, strength, and flexibility. In this comprehensive guide, we will delve into the safety considerations and best practices for working with Cuplock scaffolding.

Cuplock scaffolding is a modular system that is widely used in the construction industry for its versatility and durability. It is designed to provide a safe and stable working platform for workers at various heights. However, like any other type of scaffolding, it is essential to adhere to specific safety guidelines and best practices to ensure the well-being of the workers and the successful completion of the project.

One of the first safety considerations when working with Cuplock scaffolding is to ensure that the structure is erected by trained and competent personnel. This means that the individuals responsible for assembling the scaffolding should have the necessary knowledge and expertise to do so in a safe and secure manner. Additionally, it is crucial to inspect the scaffolding components for any signs of damage or wear before erecting the structure.

The next important aspect of safety when working with Cuplock scaffolding is to have a solid understanding of the load capacity of the system. It is imperative to know the maximum load that the scaffolding can bear and to follow strict guidelines for distributing the weight evenly across the structure. Overloading the scaffolding can lead to catastrophic failures, posing a significant risk to the workers and the project as a whole.

Furthermore, it is essential to implement proper bracing and tie-ins to ensure the stability of the Cuplock scaffolding. Bracing helps to prevent lateral movement and sway, while tie-ins connect the scaffolding to the building or structure, thereby enhancing its overall stability. By following these best practices, the risk of accidents and structural failures can be greatly reduced.

In addition to these safety considerations, it is essential to implement fall protection measures when working with Cuplock scaffolding. This includes using guardrails, toe boards, and harnesses to prevent falls from elevated platforms. Furthermore, regular inspections and maintenance of the scaffolding should be carried out to identify and address any potential hazards or issues promptly.

It is also important to provide adequate training for workers who will be using the Cuplock scaffolding. Proper training ensures that workers are familiar with the safe use of the system and are aware of the potential hazards associated with working at heights. This can help prevent accidents and injuries on the job site.

In conclusion, Cuplock scaffolding is a versatile and reliable system that offers numerous benefits for construction and maintenance projects. However, it is crucial to prioritize safety considerations and adhere to best practices when working with this type of scaffolding. By following these guidelines, workers can ensure a safe and secure working environment, and project managers can ensure the successful completion of their projects.

Maximizing the Efficiency and Flexibility of Cuplock Scaffolding Systems

Cuplock scaffolding is a versatile and efficient system that is widely used in construction projects around the world. This article aims to provide a comprehensive guide to unlocking the benefits of cuplock scaffolding, with a focus on maximizing its efficiency and flexibility.

One of the key advantages of cuplock scaffolding is its ability to provide a high level of flexibility. This system is designed to be easily adaptable to various construction requirements, making it suitable for a wide range of projects. This flexibility allows for quick and easy adjustments, reducing downtime and increasing productivity on the job site.

In addition to its flexibility, cuplock scaffolding offers a high level of efficiency. The unique design of the cuplock system allows for quick and easy assembly, saving valuable time and labor costs. This efficiency is further enhanced by the system's ability to support heavy loads, providing a safe and reliable platform for workers to perform their tasks.

Another benefit of cuplock scaffolding is its versatility. This system can be used for various applications, including but not limited to, general access, support, shoring, and suspended platforms. Its modular design allows for easy customization to suit the specific needs of a project, making it an ideal choice for construction sites of all sizes and complexities.

Moreover, cuplock scaffolding is known for its durability and stability. The unique node point connection of the cups and ledgers creates a robust and secure structure that can withstand the rigors of the construction environment. This stability not only ensures the safety of workers but also provides a reliable support system for materials and equipment.

Furthermore, cuplock scaffolding is designed with safety in mind. The system features built-in safety features, such as captive wedges and tamper-resistant components, to prevent accidental dislodgment and ensure the integrity of the structure. Additionally, the system can be easily configured with a range of accessories, such as guardrails and toe boards, to further enhance safety on the job site.

In conclusion, cuplock scaffolding offers a wide range of benefits, including flexibility, efficiency, versatility, durability, and safety. By understanding how to maximize the efficiency and flexibility of this system, construction professionals can take full advantage of its capabilities to ensure seamless and successful project execution. Whether it's for a small-scale renovation or a large-scale construction project, cuplock scaffolding is a reliable and cost-effective solution for meeting the demands of the modern construction industry.

Conclusion

In conclusion, it is clear that Cuplock scaffolding offers a wide range of benefits for construction projects, making it a versatile and efficient choice for any company. With its ease of assembly, high load-bearing capacity, and adaptability to various heights and terrains, it is no wonder that Cuplock has become a popular choice in the industry. As a company with 14 years of experience, we have seen firsthand the impact that Cuplock scaffolding can have on the efficiency and safety of our projects. We believe that by unlocking the benefits of Cuplock scaffolding, we can continue to push the boundaries of what is possible in the construction industry. So why wait? Make the switch to Cuplock scaffolding today and experience the ultimate guide to success in your projects.