Hot-Dip Galvanized Ringlock Scaffolding: 20-Year Corrosion Protection Explained

Hot-Dip Galvanized Ringlock Scaffolding: 20-Year Corrosion Protection Explained

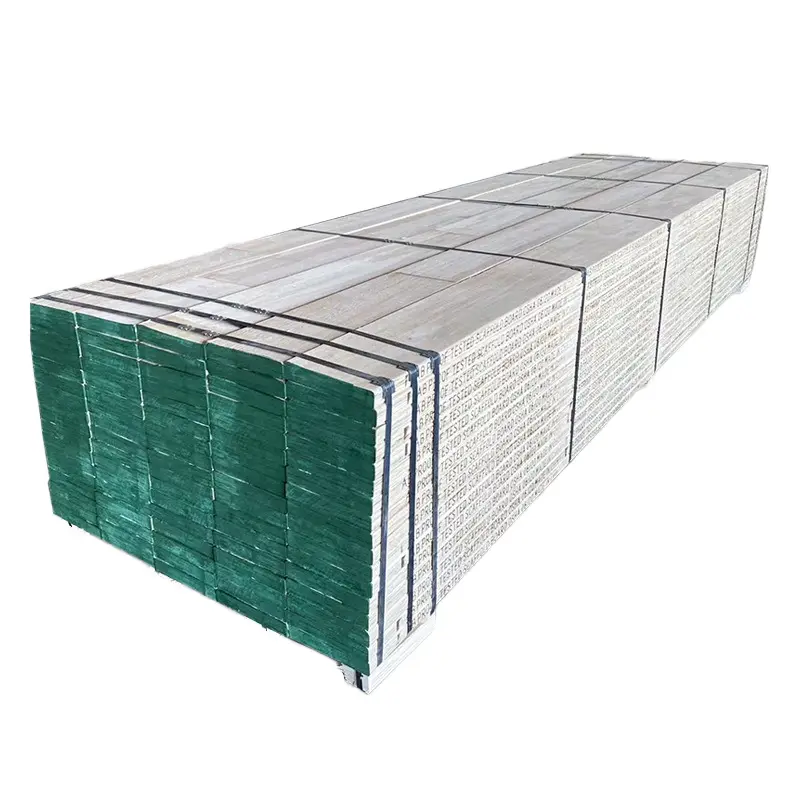

Hot-dip galvanized ringlock scaffolding is a popular choice for construction projects due to its exceptional strength, versatility, and long-term durability. One of the key benefits of this type of scaffolding is its 20-year corrosion protection, ensuring that it will withstand the elements and remain in top condition for years to come. In this article, we will delve into the details of hot-dip galvanized ringlock scaffolding and explain how its corrosion protection works.

The Process of Hot-Dip Galvanization

Hot-dip galvanization is a process that involves immersing steel components in a bath of molten zinc to create a protective coating. The zinc coating effectively acts as a sacrificial layer, providing a barrier between the steel and the surrounding environment. During the galvanization process, the steel components are cleaned, pickled, fluxed, and then dipped into the molten zinc bath at temperatures exceeding 800 degrees Fahrenheit. This process ensures a uniform coating that adheres tightly to the steel surface, offering long-lasting protection against corrosion.

The hot-dip galvanization process results in a durable coating that can withstand the harshest conditions, including exposure to moisture, chemicals, and abrasion. Unlike other types of protective coatings, such as paint or powder coating, hot-dip galvanization does not require periodic maintenance or touch-ups. This makes hot-dip galvanized ringlock scaffolding a cost-effective and low-maintenance solution for construction projects of all sizes.

The Benefits of Corrosion Protection

The 20-year corrosion protection provided by hot-dip galvanized ringlock scaffolding offers numerous benefits to construction companies and workers. One of the primary advantages is the extended lifespan of the scaffolding system, reducing the need for frequent replacements and repairs. This not only saves time and money but also ensures the safety of workers who rely on the scaffolding for support and access to elevated areas.

In addition to its longevity, the corrosion protection of hot-dip galvanized ringlock scaffolding enhances its overall performance and reliability on the job site. The zinc coating helps prevent rust and deterioration, maintaining the structural integrity of the scaffolding components over time. This is especially important in environments with high humidity, saltwater exposure, or other corrosive elements that can compromise the strength and stability of traditional scaffolding systems.

Applications of Hot-Dip Galvanized Ringlock Scaffolding

Hot-dip galvanized ringlock scaffolding is suitable for a wide range of construction applications, including residential, commercial, industrial, and infrastructure projects. Its versatility and adaptability make it an ideal choice for complex structures, temporary support systems, and scaffolding towers. The secure ringlock connections and modular design of the system allow for easy assembly, disassembly, and reconfiguration to meet the specific requirements of each project.

One of the key advantages of hot-dip galvanized ringlock scaffolding is its ability to withstand harsh environmental conditions, making it well-suited for outdoor construction projects exposed to the elements. The corrosion protection provided by the galvanized coating ensures that the scaffolding will remain sturdy, reliable, and safe for use in all weather conditions. Whether used for building facades, bridge construction, or maintenance work, hot-dip galvanized ringlock scaffolding offers unparalleled durability and performance.

Cost-Effectiveness and Long-Term Value

While hot-dip galvanized ringlock scaffolding may have a higher upfront cost compared to other types of scaffolding, its long-term durability and corrosion protection offer significant cost savings over time. The 20-year corrosion protection provided by the galvanized coating eliminates the need for frequent replacements, repairs, and maintenance, reducing overall project expenses and downtime. This results in a higher return on investment for construction companies and contractors who choose hot-dip galvanized ringlock scaffolding for their projects.

In addition to its cost-effectiveness, hot-dip galvanized ringlock scaffolding offers long-term value in terms of safety, performance, and reliability. The corrosion-resistant properties of the galvanized coating ensure that the scaffolding system will maintain its structural integrity and load-bearing capacity throughout its lifespan. This enhances worker safety, minimizes the risk of accidents or structural failures, and promotes efficiency and productivity on the job site. By investing in hot-dip galvanized ringlock scaffolding, construction companies can achieve superior results and long-lasting performance in their projects.

In conclusion, hot-dip galvanized ringlock scaffolding offers 20-year corrosion protection that enhances its durability, longevity, and performance on construction sites. The galvanized coating provides a robust barrier against rust, corrosion, and deterioration, ensuring that the scaffolding system remains safe, reliable, and structurally sound over time. With its cost-effectiveness, versatility, and low-maintenance requirements, hot-dip galvanized ringlock scaffolding is an excellent choice for construction projects that demand high-quality, long-lasting support systems. By understanding the benefits and applications of hot-dip galvanized ringlock scaffolding, construction companies and workers can make informed decisions and achieve successful outcomes in their building endeavors.