The Importance Of Beam Brackets In Cuplock Systems

Metal beam brackets play a crucial role in the construction industry, especially in cuplock systems. These brackets provide essential support and stability to the beams, ensuring the safety and durability of the structure. In this article, we will explore the importance of beam brackets in cuplock systems and how they contribute to the overall strength and integrity of the construction project.

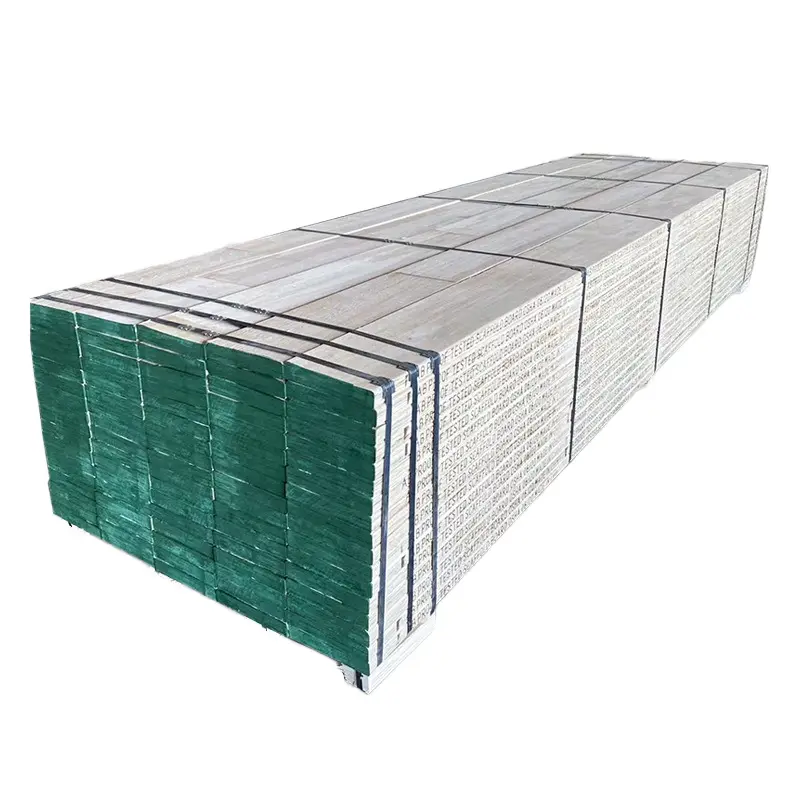

Metal beam brackets are designed to provide a secure connection between the beams and the cuplock system. They are typically made of high-quality steel or aluminum to ensure maximum strength and durability. These brackets come in various shapes and sizes to accommodate different beam sizes and configurations. When properly installed, beam brackets help distribute the load evenly across the beams, preventing any potential weak points or structural failures.

Enhanced Structural Stability

One of the key benefits of using beam brackets in cuplock systems is the enhanced structural stability they provide. By securely fastening the beams to the cuplock system, the brackets help prevent any lateral movement or displacement, even under heavy loads or strong winds. This added stability is crucial in ensuring the safety of workers and the structural integrity of the building.

In addition to preventing lateral movement, beam brackets also help minimize vertical deflection in the beams. This is particularly important in tall structures where deflection can lead to uneven loads and potential structural failures. By supporting the beams at strategic points along their length, the brackets help maintain the desired shape and alignment of the structure, ensuring its overall stability.

Improved Load Distribution

Another important function of beam brackets in cuplock systems is their role in distributing the loads effectively across the beams. When a structure is subjected to various loads, such as dead loads, live loads, and wind loads, it is essential to ensure that these loads are evenly distributed to prevent any localized stress concentrations. Beam brackets help achieve this by connecting the beams to the cuplock system and transferring the loads to the support structure efficiently.

By distributing the loads evenly across the beams, beam brackets help prevent overloading and potential failures in the structure. This is especially critical in high-rise buildings or bridges where the loads can be substantial. Proper load distribution not only ensures the safety of the structure but also prolongs its service life by minimizing wear and tear on the beams.

Ease of Installation and Maintenance

One of the advantages of using beam brackets in cuplock systems is the ease of installation and maintenance they offer. Unlike traditional welding or bolting methods, which can be time-consuming and labor-intensive, beam brackets can be quickly and securely attached to the beams using simple tools. This not only saves time and labor costs during construction but also allows for easy adjustments or replacements of the brackets when needed.

Furthermore, beam brackets require minimal maintenance once installed, as they are designed to withstand harsh environmental conditions and heavy loads. Routine inspections and occasional tightening of the bracket fasteners are usually all that is needed to ensure the continued performance of the brackets. This ease of installation and maintenance makes beam brackets a cost-effective and efficient solution for supporting beams in cuplock systems.

Versatility and Adaptability

Beam brackets in cuplock systems are highly versatile and adaptable to a wide range of construction applications. Whether used in buildings, bridges, industrial structures, or temporary shoring systems, beam brackets can be customized to meet the specific requirements of the project. With adjustable designs and multiple connection options, beam brackets can accommodate various beam sizes, shapes, and angles, making them suitable for diverse construction projects.

Moreover, beam brackets can be easily integrated with other support elements, such as diagonal braces, horizontal beams, or ledger brackets, to create a comprehensive cuplock system that enhances the overall stability and strength of the structure. This versatility and adaptability make beam brackets an essential component in modern construction practices, as they provide a flexible and reliable solution for supporting beams in different applications.

In conclusion, beam brackets play a vital role in cuplock systems by providing enhanced structural stability, improved load distribution, ease of installation and maintenance, and versatility and adaptability to various construction projects. By securely connecting the beams to the cuplock system and distributing the loads effectively, beam brackets ensure the safety, durability, and integrity of the structure. Whether used in buildings, bridges, or industrial structures, beam brackets are an essential component that contributes to the overall strength and stability of the construction project.