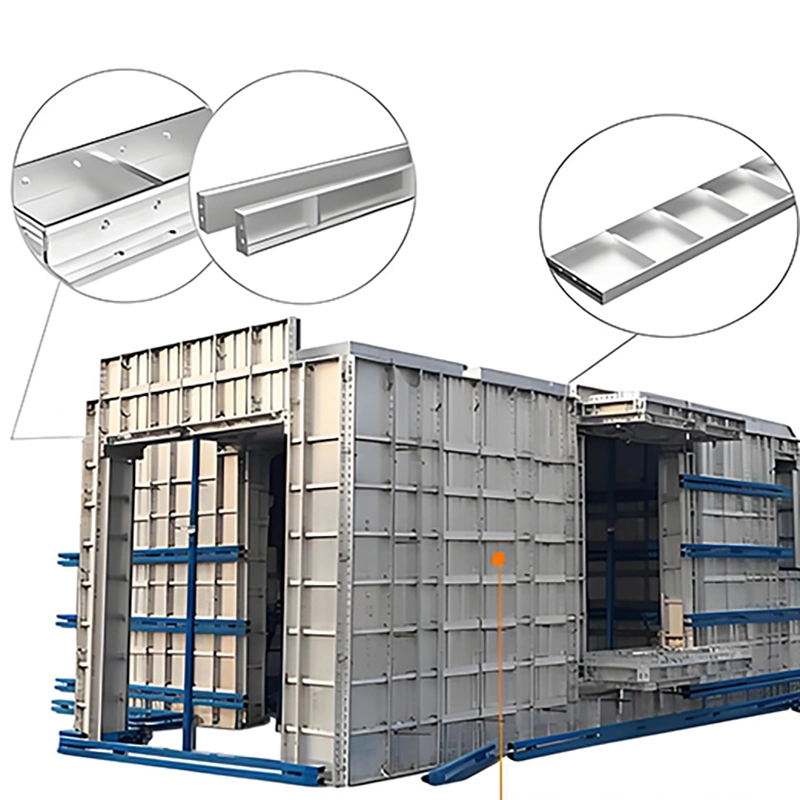

Modern Design Adjustable Modular Aluminum Formwork for Wall Slab Columns Concrete Column Formwork

Product Introduction

Modular Vertical Aluminum Formwork System Easy Installation Adjustable Column & Shear Wall for Modern Concrete Construction

Modern Modular Aluminum Panel Formwork System for Construction House Column Wall Slab for Concrete Formwork Durable Lightweight

Modern Design Easy Assembly Aluminum Building Concrete Formwork System Efficient Construction Solution

Modern 3D Model Design for Aluminium Formwork Building Material Construction Concrete

Modern Designed Monolithic Concrete Structure Aluminum Formwork Assembled Work Table for Building Houses

Product Display

Product advantages

Advantages of Aluminum Alloy Formwork Construction

Simple Assembly and High Construction EfficiencyAluminum alloy formworks are the lightest among current metal formworks, A single worker-can easily move, install, dismantle, and transport them, The assembly is straightforwardaseach piece of fomwork and componentis used in the same position on each floor. Worker-scan master the construction technigues quickly with minimal training, as the installationanddismantling processes require only manpower, no additional machinery, making opera-tionssimple and convenient.

High Quality and Stable Performance

Aluminum alloy formworks ensure excellent horizontal and vertical alianment, and since the-formworks do not absorb water,the quality of concrete molding is high. This eliminates the-need for costly and time-consuming plastering work, and tiles can be directly adhered tobothinterior and exterior walls, Additionally, as aluminum alloy fommwork svstems aremanufac-tured with precise computer sofware and machinery accordina to architecturadrawinas, theconstructed buildinas are hiahly accurate, particularly in the placement ancdimensions ofdoors, windows, and utilities, effectivelv reducina the amount of constructiormaterialsneeded later and savina costs

Standardization, Modularity, and Systematization

Aluminum alloy formworks are produced through factory processes including profileextru-sion, processing, and surface coating, with factory-level assembly and quality contrcensuringprecise dimensions and reducing construction errors at the site due to designfactors, Thisminimizes human errors in structural dimensions

High Turnover Number and Cost-Efficiency

The aluminum alloy formwork and support systems utilize a set that can be sliahtly modifed-and reused in subseauent new constructions, thus providina a lona-term reduction inform-work cost distribution, The waste from aluminum alloy fommworks is fully recycable.

Rapid Construction Progress and Shorter Project Duration

Aluminum alloy formwork systems are produced and standardized in factories, makinaassem-bly simple and convenient, thereby reducing installation and dismantling time. Thesystem'sspecially designed support structure achieves mature early-stripping technology,which hasbeen accepted and successfuly used wordwide, typically achievina constructiolprogress ofone floor every four to five days.

FAQ