Cuplock Scaffolding For Power Plant Maintenance: Safety First

Engaging Introduction:

When it comes to maintenance work in power plants, safety is paramount. The maintenance of power plants involves working at heights, handling heavy equipment, and dealing with various hazards. To ensure the safety of workers during maintenance activities, using the right scaffolding system is crucial. Cuplock scaffolding is a versatile and reliable system that is ideal for power plant maintenance. In this article, we will explore the importance of safety in power plant maintenance and how cuplock scaffolding can help achieve it.

The Importance of Safety in Power Plant Maintenance

Safety in power plant maintenance is of utmost importance due to the potential risks involved in working in such environments. Power plants have high voltage equipment, heavy machinery, confined spaces, and elevated platforms that pose serious safety hazards to workers. Accidents in power plants can result in injuries, fatalities, and damage to equipment. Therefore, following strict safety protocols and using proper safety equipment is essential to prevent accidents and ensure the well-being of workers.

Common Safety Hazards in Power Plants

There are several common safety hazards that workers face in power plants, including falls from heights, electric shocks, exposure to hazardous chemicals, and confined space accidents. Working at heights is a common requirement in power plant maintenance, where workers need to access elevated platforms, equipment, and structures. Falls from heights can result in serious injuries or even death if proper fall protection measures are not in place. Electric shocks are another significant risk in power plants due to the presence of high voltage equipment. Workers need to be trained in electrical safety practices and use insulated tools to prevent electric shocks.

Benefits of Using Cuplock Scaffolding for Power Plant Maintenance

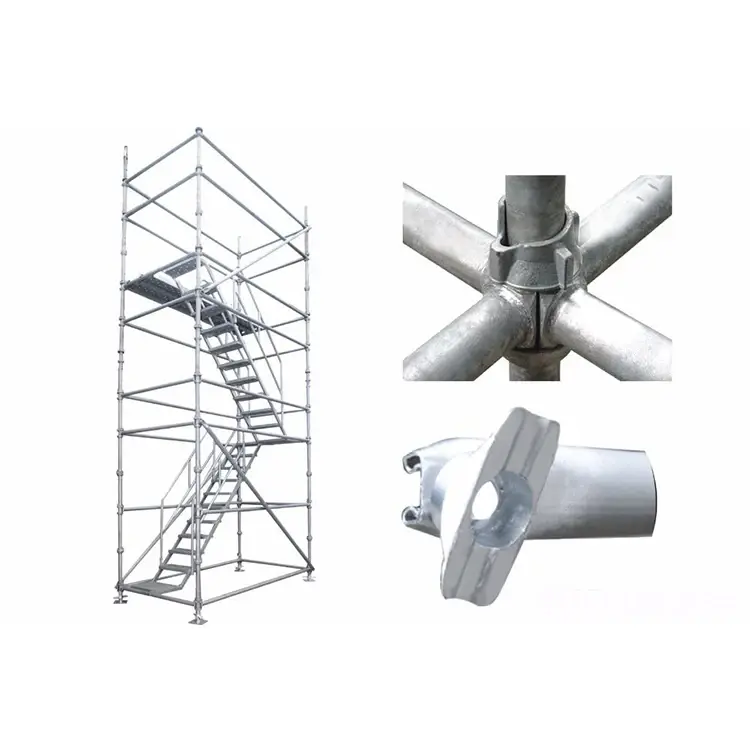

Cuplock scaffolding offers numerous benefits for power plant maintenance, making it an ideal choice for ensuring safety and efficiency. This system is easy to assemble, versatile, and can adapt to various shapes and sizes, making it suitable for different maintenance tasks in power plants. The cuplock system features a unique node point that allows for a fast and secure connection, increasing the overall safety of the scaffold. Additionally, cuplock scaffolding is highly durable and can withstand heavy loads, providing a stable and secure working platform for maintenance activities at power plants.

Enhancing Safety with Cuplock Scaffolding Accessories

In addition to the standard components of cuplock scaffolding, various accessories can be used to enhance safety and efficiency during power plant maintenance. Guardrails, toe boards, and safety nets can be installed to prevent falls from elevated platforms and provide a safe working environment for workers. Staircases and access ladders can be added to allow easy and safe access to different levels of the scaffold. Additionally, personal protective equipment such as safety harnesses, helmets, and gloves should be worn by workers at all times to prevent injuries and accidents while working on cuplock scaffolding.

Training and Certification for Power Plant Maintenance Workers

Another crucial aspect of ensuring safety in power plant maintenance is providing adequate training and certification for workers. Maintenance personnel working in power plants should undergo comprehensive training on safety procedures, equipment operation, and emergency protocols. Workers should be familiar with the specific hazards present in power plants and how to mitigate risks effectively. Additionally, workers should be certified to operate heavy machinery, work at heights, and handle hazardous materials safely. Regular safety refresher courses and emergency drills should be conducted to ensure that workers remain updated on safety practices and protocols.

Summary:

In conclusion, safety should always be the top priority in power plant maintenance to prevent accidents, injuries, and fatalities. Using cuplock scaffolding can greatly enhance safety during maintenance activities in power plants by providing a stable and secure working platform for workers. The versatility, durability, and ease of assembly of cuplock scaffolding make it an excellent choice for power plant maintenance. By incorporating safety measures such as guardrails, toe boards, and personal protective equipment, workers can minimize risks and work safely at heights. Training and certification for maintenance workers are essential to ensure that they are well-prepared to handle the specific safety hazards present in power plants. By prioritizing safety and utilizing the right equipment and practices, power plant maintenance can be conducted efficiently and safely.