What Makes The Cuplock Scaffolding Different From Others?

Scaffolding is an essential tool in the construction industry, providing support and safety for workers at elevated heights. Among the various types of scaffolding available, Cuplock scaffolding stands out for its unique design and ease of use. In this article, we will explore what makes Cuplock scaffolding different from others and why it is a popular choice for construction projects worldwide.

Key Features of Cuplock Scaffolding

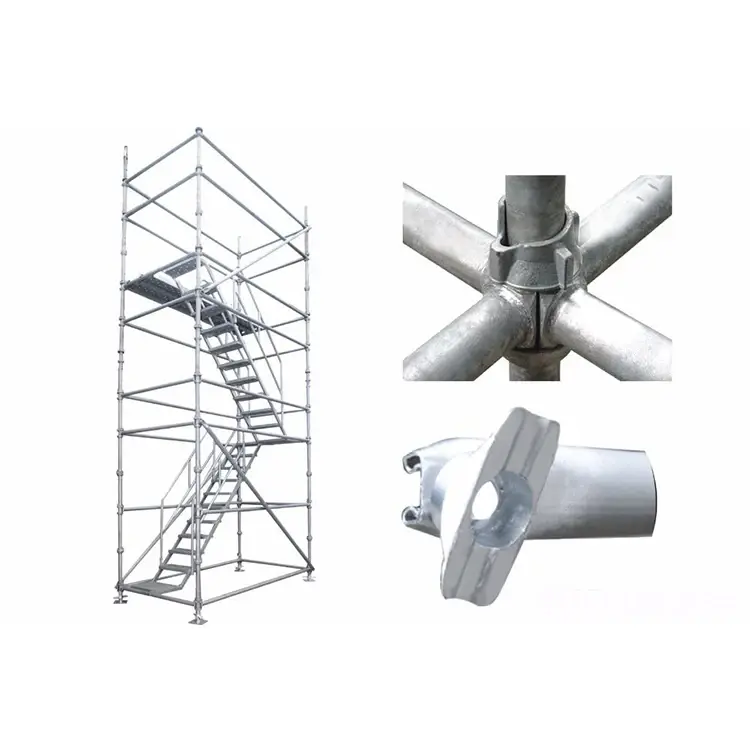

Cuplock scaffolding is known for its versatility and efficiency, making it a preferred choice for contractors and builders. One of the key features of Cuplock scaffolding is its unique node point connection system. The nodes are designed with cups that allow for easy and fast assembly without the need for nuts and bolts. This innovative design not only saves time but also enhances the overall stability of the scaffold structure.

Moreover, Cuplock scaffolding is modular in nature, meaning that it can be easily adapted to suit various construction requirements. The standard verticals (standards) and horizontals (ledgers) can be combined in different configurations to create a scaffold platform of any size or shape. This flexibility makes Cuplock scaffolding ideal for projects with complex or irregular layouts, where traditional scaffolding systems may not be practical.

Another notable feature of Cuplock scaffolding is its high load-bearing capacity. The durable steel components used in the system are designed to withstand heavy loads, making it suitable for supporting workers, materials, and equipment at construction sites. This robust construction ensures the safety and stability of the scaffold, giving workers peace of mind while working at heights.

Advantages of Cuplock Scaffolding

Cuplock scaffolding offers several advantages over other types of scaffolding systems. One of the main benefits of Cuplock scaffolding is its speed of assembly. The node point connection system allows for quick and easy installation, reducing labor costs and increasing productivity on the job site. This time-saving feature makes Cuplock scaffolding an efficient choice for construction projects with tight deadlines.

Additionally, Cuplock scaffolding is highly versatile and can be used for a wide range of applications. Whether it's for building construction, bridge maintenance, or industrial projects, Cuplock scaffolding can adapt to different site conditions and requirements. The modular design of Cuplock scaffolding allows for easy reconfiguration and customization, making it a cost-effective solution for various construction needs.

Another advantage of Cuplock scaffolding is its safety features. The secure node point connections and sturdy steel components ensure the stability and reliability of the scaffold structure. This reduces the risk of accidents and injuries on the job site, making Cuplock scaffolding a preferred choice for ensuring worker safety during construction activities.

Applications of Cuplock Scaffolding

Cuplock scaffolding is widely used in the construction industry for a variety of applications. One of the common uses of Cuplock scaffolding is for building construction, where it provides support for workers, materials, and equipment at elevated heights. The versatility and adaptability of Cuplock scaffolding make it suitable for constructing high-rise buildings, residential complexes, commercial structures, and more.

Moreover, Cuplock scaffolding is also used for bridge construction and maintenance projects. The ability to create custom scaffold platforms of any size and shape makes Cuplock scaffolding ideal for supporting bridge girders, beams, and decks. Its high load-bearing capacity and stability make it a reliable choice for ensuring the safety of workers and equipment during bridge construction activities.

In addition to building and bridge projects, Cuplock scaffolding is commonly used in industrial settings for plant maintenance, installation work, and access solutions. The flexibility and strength of Cuplock scaffolding make it well-suited for industrial applications, where robust and reliable scaffolding systems are required to support heavy machinery and equipment.

Comparing Cuplock Scaffolding with Other Systems

When compared to other types of scaffolding systems, Cuplock scaffolding offers several distinct advantages. One of the main differences between Cuplock scaffolding and traditional tube and coupler scaffolding is the speed of assembly. The cup and blade design of Cuplock scaffolding allows for faster and easier installation, saving time and labor costs on the job site.

Moreover, Cuplock scaffolding is more versatile and adaptable than frame scaffolding systems. The modular nature of Cuplock scaffolding enables contractors to create customized scaffold platforms to suit different project requirements. This flexibility sets Cuplock scaffolding apart from fixed-frame systems, allowing for greater efficiency and productivity during construction activities.

Another key difference between Cuplock scaffolding and other systems is its load-bearing capacity. Cuplock scaffolding is designed to support heavy loads, making it suitable for projects that require strong and stable scaffold structures. This makes Cuplock scaffolding a preferred choice for construction projects with high load requirements, where safety and reliability are paramount.

Future Trends in Cuplock Scaffolding

As the construction industry continues to evolve, so does the technology and design of scaffolding systems. Looking ahead, future trends in Cuplock scaffolding are expected to focus on enhancing safety, efficiency, and sustainability. New innovations in scaffold materials, connection systems, and design configurations are likely to improve the performance and capabilities of Cuplock scaffolding for future construction projects.

One of the potential trends in Cuplock scaffolding is the integration of digital technologies for enhanced safety and productivity. Smart sensors and monitoring devices could be used to track scaffold performance, detect potential hazards, and ensure compliance with safety standards. This digital integration could revolutionize how Cuplock scaffolding is used and maintained on construction sites, leading to safer working conditions and better project outcomes.

Additionally, sustainability is becoming an increasingly important factor in construction practices, including scaffolding solutions. Future trends in Cuplock scaffolding may focus on eco-friendly materials, reusable components, and energy-efficient designs to reduce the environmental impact of construction activities. By prioritizing sustainability in scaffold construction and usage, Cuplock scaffolding can contribute to a more sustainable and greener future for the construction industry.

In conclusion, Cuplock scaffolding stands out from other scaffolding systems for its unique design, versatility, efficiency, and safety features. Its innovative node connection system, modular construction, and high load-bearing capacity make it a popular choice for construction projects worldwide. With ongoing developments in technology and design, the future of Cuplock scaffolding looks promising, with a focus on enhancing safety, efficiency, and sustainability in the construction industry. Whether it's for building construction, bridge projects, or industrial applications, Cuplock scaffolding continues to set the standard for reliable and robust scaffold solutions.