What Type Of Pipe Is Used For Scaffolding?

Metal scaffolding is a common sight in the construction industry, allowing workers to safely reach heights during building projects. One key component of scaffolding is the pipes used to create the framework. The type of pipe chosen for scaffolding plays a crucial role in the overall stability and durability of the structure. In this article, we will explore the various types of pipes used for scaffolding and their unique characteristics.

Metal pipes are commonly used for scaffolding due to their strength, durability, and ease of assembly. Different types of metal pipes are used for scaffolding, each with its own set of pros and cons. It is essential to understand the differences between these pipes to ensure the safety and stability of the scaffolding structure. Let's delve into the different types of pipes used for scaffolding in detail.

Steel Pipes

Steel pipes are the most common type of pipe used for scaffolding. They are known for their strength, durability, and resistance to corrosion. Steel pipes come in various sizes and thicknesses, making them versatile for different scaffolding needs. The high tensile strength of steel pipes makes them suitable for supporting heavy loads and withstanding adverse weather conditions. Additionally, steel pipes can be easily welded together, providing a secure and stable scaffolding structure.

One of the primary advantages of steel pipes for scaffolding is their long lifespan. Steel pipes are designed to last for years without rusting or corroding, ensuring the safety of workers on the scaffolding. The versatility of steel pipes also allows for customization based on specific project requirements. However, steel pipes can be heavy and may require machinery or equipment for assembly, which can increase construction costs.

Galvanized Steel Pipes

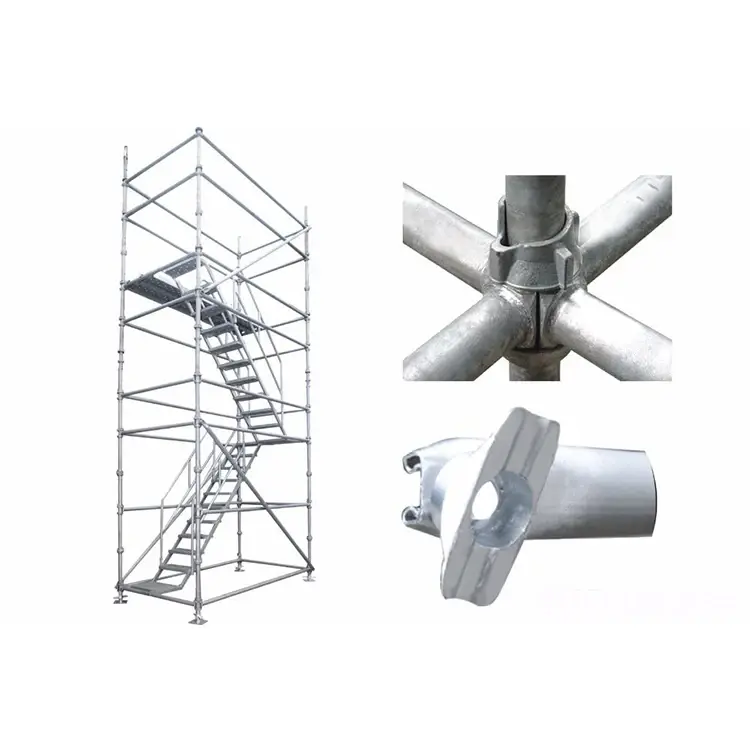

Galvanized steel pipes are another popular choice for scaffolding due to their added layer of protection against corrosion. These pipes are coated with a layer of zinc, which acts as a barrier against rust and other environmental factors. Galvanized steel pipes are highly durable and can withstand harsh conditions, making them ideal for outdoor scaffolding projects. The zinc coating also provides a sleek and professional appearance to the scaffolding structure.

One of the main benefits of galvanized steel pipes is their cost-effectiveness. While slightly more expensive than regular steel pipes, the added protection against corrosion can extend the lifespan of the scaffolding, reducing the need for frequent repairs or replacements. Galvanized steel pipes are also easy to maintain and clean, making them a low-maintenance option for scaffolding projects. However, galvanized steel pipes may require specialized tools for cutting and welding due to the zinc coating.

Aluminum Pipes

Aluminum pipes are lightweight and corrosion-resistant, making them an excellent choice for scaffolding in industrial or marine environments. Aluminum pipes are easy to handle and transport, reducing the labor costs associated with assembly and disassembly. The lightweight nature of aluminum pipes also makes them ideal for projects that require frequent relocation of the scaffolding structure. Despite being lightweight, aluminum pipes are strong and durable, capable of supporting heavy loads.

One of the key advantages of aluminum pipes for scaffolding is their resistance to corrosion. Aluminum does not rust, making it suitable for outdoor scaffolding projects exposed to moisture and humidity. Additionally, aluminum pipes do not require any protective coatings, further reducing maintenance costs. However, aluminum pipes are more expensive than steel pipes, which can impact overall project costs. Aluminum pipes may also have lower tensile strength compared to steel pipes, requiring additional support for heavy loads.

Composite Pipes

Composite pipes are a modern alternative to traditional metal pipes for scaffolding. These pipes are made from a combination of materials, such as fiberglass and resin, to create a lightweight and durable scaffolding solution. Composite pipes are non-conductive, making them ideal for electrical work or projects where insulation is required. Additionally, composite pipes are resistant to corrosion, chemicals, and UV rays, ensuring their longevity in various environments.

One of the primary advantages of composite pipes for scaffolding is their lightweight nature. Composite pipes are significantly lighter than metal pipes, making them easy to handle and transport on-site. The non-conductive properties of composite pipes also reduce the risk of electrical hazards, making them a safe choice for projects involving power lines or sources. However, composite pipes may have a higher upfront cost compared to traditional metal pipes, which can impact overall project budgets. Additionally, composite pipes may require specialized tools for cutting and joining, adding to construction time and costs.

Plastic Pipes

Plastic pipes are another alternative to traditional metal pipes for scaffolding, known for their lightweight and cost-effective properties. Plastic pipes are easy to handle and assemble, making them a popular choice for smaller scaffolding projects or temporary structures. Plastic pipes are available in various sizes and colors, allowing for easy identification and customization based on project requirements. Despite their lightweight nature, plastic pipes can still provide sufficient strength and stability for most scaffolding applications.

One of the main advantages of plastic pipes for scaffolding is their affordability. Plastic pipes are generally more budget-friendly than metal pipes, making them a cost-effective choice for contractors on a tight budget. Plastic pipes are also resistant to corrosion, chemicals, and moisture, ensuring their durability in different environments. However, plastic pipes may have lower tensile strength compared to metal pipes, requiring additional support for heavy loads. Additionally, plastic pipes may deform under extreme heat or pressure, limiting their use in certain construction projects.

In conclusion, the type of pipe used for scaffolding plays a crucial role in the overall safety, stability, and durability of the structure. Steel pipes are the most common choice for scaffolding due to their strength and versatility. Galvanized steel pipes offer added protection against corrosion, while aluminum pipes provide a lightweight and corrosion-resistant alternative. Composite pipes and plastic pipes are modern alternatives with unique properties that cater to specific project requirements.

It is essential to consider the specific needs of the project, budget constraints, and environmental factors when choosing the type of pipe for scaffolding. By understanding the characteristics and benefits of each pipe material, contractors can make informed decisions to ensure the success of their scaffolding projects. Whether opting for traditional steel pipes or exploring modern alternatives, selecting the right pipe for scaffolding is crucial for creating a safe and reliable construction framework.