Different Types Of Ringlock Scaffolding Steel Planks

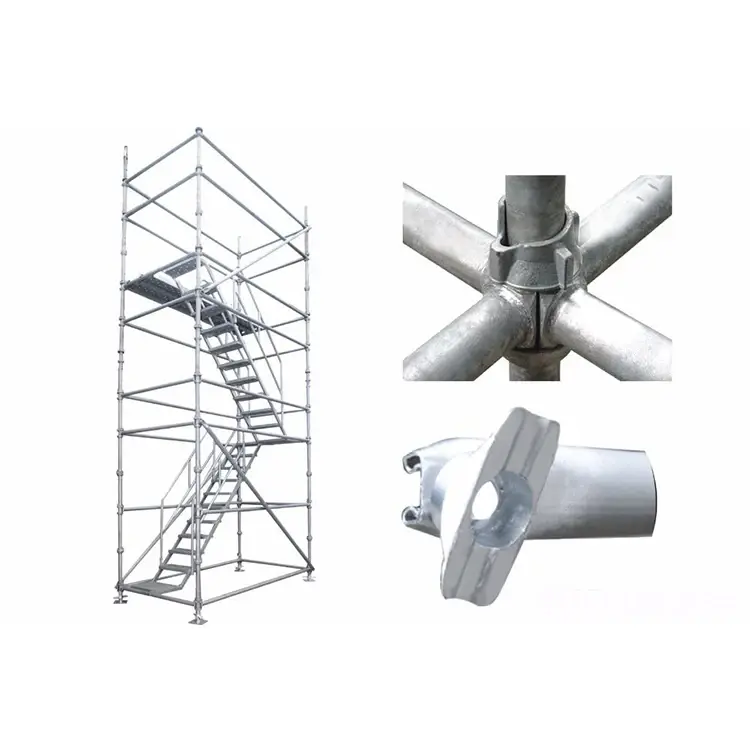

Scaffolding is an essential component in the construction industry, providing temporary support for workers and materials during the construction or maintenance of buildings. Among the various types of scaffolding available, ringlock scaffolding is known for its versatility, durability, and safety features. One crucial element of ringlock scaffolding is steel planks. Steel planks are used to create a stable walking surface for workers and support materials on the scaffold.

Standard Steel Planks

Standard steel planks are the most common type of steel planks used in ringlock scaffolding. These steel planks are typically made from high-quality steel and are designed to withstand heavy loads. Standard steel planks are available in various lengths, ranging from 7 feet to 10 feet, and widths of 19 inches. The surface of standard steel planks is usually textured to provide better traction and reduce the risk of slipping. These steel planks are easy to install and remove, making them a popular choice among construction professionals.

Non-slip Steel Planks

Non-slip steel planks are designed to provide an extra layer of safety on the scaffolding. These steel planks feature a non-slip surface that helps prevent accidents caused by slippery conditions. The non-slip surface is achieved through various methods, such as adding a textured coating or welding studs onto the steel planks. Non-slip steel planks are particularly useful in areas where moisture or other slippery substances may be present, such as during rainy weather or when working with liquids on the scaffold.

Aluminum Steel Planks

Aluminum steel planks offer a lightweight alternative to traditional steel planks. While aluminum is not as strong as steel, aluminum steel planks are still capable of supporting heavy loads and providing a stable working surface. Aluminum steel planks are corrosion-resistant, making them an excellent choice for outdoor construction projects or in environments with high humidity. Additionally, the lightweight nature of aluminum steel planks makes them easy to transport and install, reducing labor costs and increasing productivity on the construction site.

Adjustable Steel Planks

Adjustable steel planks are designed to provide flexibility in the height of the working surface on the scaffold. These steel planks feature adjustable hooks or pins that allow the plank to be set at different heights within the scaffold system. Adjustable steel planks are ideal for uneven terrain or when working at different levels on the scaffold. The ability to adjust the height of the steel planks ensures that workers have a safe and level surface to work on, reducing the risk of accidents and injuries.

Perforated Steel Planks

Perforated steel planks are steel planks that feature small holes or slots along the surface. These perforations help improve drainage on the scaffold, allowing water to flow through the steel planks and reduce the risk of pooling water. Perforated steel planks are ideal for outdoor construction projects or in areas where moisture may be present, such as near water features or in humid environments. The perforations also provide better traction for workers, reducing the risk of slipping and falling on the scaffold.

In conclusion, steel planks are an essential component of ringlock scaffolding, providing a stable and safe working surface for construction professionals. There are various types of steel planks available, each with its unique features and benefits. Whether you need standard steel planks for general construction work or non-slip steel planks for increased safety, there is a steel plank option to suit your specific needs. Consider the type of project, environmental conditions, and safety requirements when choosing the right steel planks for your ringlock scaffolding system.