Galvanized Cuplock Scaffolding: Why Corrosion Resistance Matters

As construction projects become more sophisticated and demanding, the need for high-quality scaffolding systems has never been more critical. Galvanized Cuplock scaffolding has emerged as a popular choice due to its strength, durability, and versatility. One of the key factors that set Galvanized Cuplock scaffolding apart from other types is its corrosion resistance. In this article, we delve into why corrosion resistance matters in scaffolding and how Galvanized Cuplock scaffolding addresses this crucial factor.

What is Galvanized Cuplock Scaffolding?

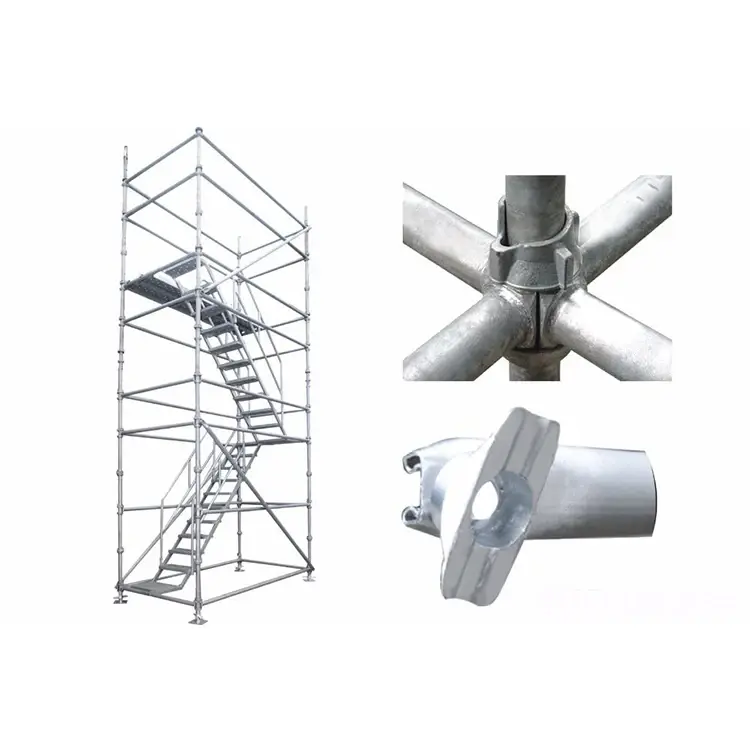

Galvanized Cuplock scaffolding is a type of modular scaffolding system that is renowned for its quick assembly and superior load-bearing capacity. The system features unique cup joints that allow vertical and horizontal components to be connected swiftly and securely without the need for nuts and bolts. This innovative design not only enhances the stability of the scaffolding but also reduces the time and labor required for installation and dismantling.

The Importance of Corrosion Resistance

Corrosion is a natural process that occurs when metals are exposed to moisture, oxygen, and other environmental factors. In the case of scaffolding systems, corrosion can weaken the structure over time, compromising its safety and stability. This is particularly concerning in construction projects that are located in coastal areas or environments with high levels of humidity or pollution. Corrosion resistance is, therefore, essential to ensure the longevity and reliability of scaffolding systems, especially those that are subjected to harsh outdoor conditions.

How Galvanized Cuplock Scaffolding Addresses Corrosion

Galvanized Cuplock scaffolding is made from high-quality steel that has been hot-dip galvanized to protect it from corrosion. The galvanization process involves coating the steel components with a layer of zinc, which acts as a physical barrier against moisture and other corrosive elements. This protective layer not only prevents the steel from rusting but also extends the lifespan of the scaffolding system, making it a cost-effective investment in the long run.

The Benefits of Corrosion-Resistant Scaffolding

Investing in corrosion-resistant scaffolding systems like Galvanized Cuplock can offer a range of benefits to construction companies and contractors. Firstly, it ensures the safety of workers and the structural integrity of the building by minimizing the risk of scaffolding failure due to corrosion-induced weakening. Secondly, it reduces maintenance costs and downtime associated with repairing or replacing corroded components. Lastly, it enhances the aesthetics of the scaffolding, as the galvanized finish gives it a sleek and professional look.

Considerations When Choosing Galvanized Cuplock Scaffolding

When selecting Galvanized Cuplock scaffolding for a project, there are several factors to consider to ensure that the system meets the specific requirements of the job site. It is important to assess the environmental conditions, such as exposure to saltwater or industrial pollutants, to determine the level of corrosion resistance needed. Additionally, the load-bearing capacity, flexibility, and ease of assembly of the scaffolding should be taken into account to ensure that it can support the intended use safely and efficiently.

In conclusion, corrosion resistance is a crucial consideration when choosing scaffolding systems for construction projects. Galvanized Cuplock scaffolding offers a reliable solution that not only meets the high standards of strength and durability required in the industry but also protects against the damaging effects of corrosion. By investing in corrosion-resistant scaffolding systems, construction companies can ensure the safety, longevity, and cost-effectiveness of their projects in the long term.