Scaffolding Inspection Guide: Ensuring Site Safety And Compliance

Introduction:

Scaffolding is a crucial part of many construction projects, providing a safe and stable platform for workers to carry out their tasks at height. However, the safety of scaffolding can be compromised if it is not regularly inspected and maintained. In this guide, we will discuss the importance of scaffolding inspections in ensuring site safety and compliance with regulations. We will cover the key aspects of a thorough inspection process and provide tips on how to spot potential issues before they become a safety hazard.

Understanding the Importance of Scaffolding Inspections

Scaffolding inspections are a vital part of any construction project to ensure the safety of workers who rely on these structures to perform their duties at height. Regular inspections help to identify any damage, wear, or faults in the scaffolding system that could pose a risk to workers' safety. By conducting routine inspections, construction companies can prevent accidents, injuries, and even fatalities that may result from faulty scaffolding.

Inspecting scaffolding also plays a crucial role in ensuring compliance with local regulations and industry standards. OSHA (Occupational Safety and Health Administration) and other regulatory bodies have stringent requirements for scaffold safety, including regular inspections by competent persons. Failing to comply with these regulations can result in hefty fines, legal liabilities, and even project delays. Therefore, it is essential for construction companies to prioritize scaffolding inspections to meet regulatory requirements and protect the well-being of their workers.

The Scaffolding Inspection Process

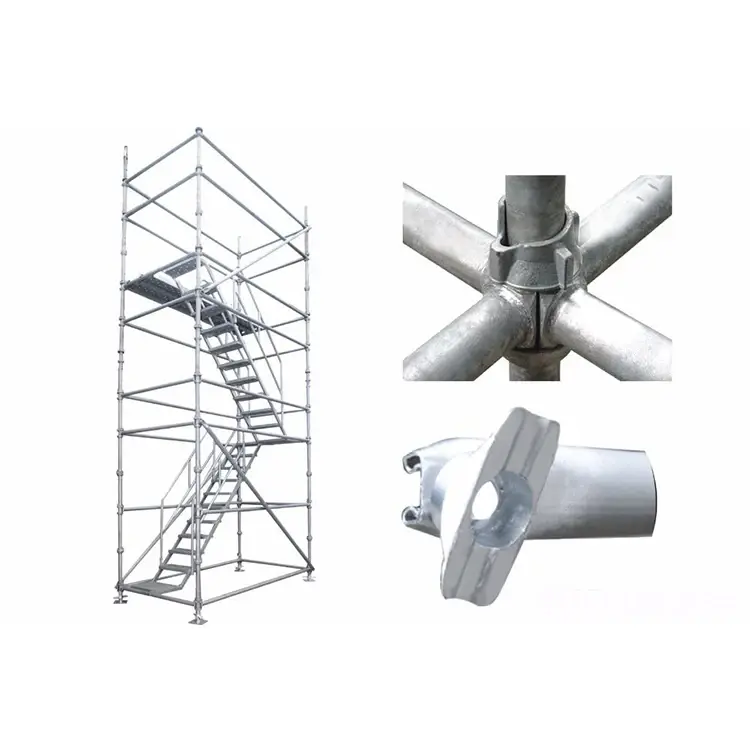

The scaffolding inspection process involves a comprehensive evaluation of the entire scaffold structure to identify any potential hazards or defects. Inspections are typically carried out by a competent person with the necessary training and experience to assess the safety and stability of the scaffold. The inspector will carefully examine various components of the scaffolding, including platforms, guardrails, toe boards, bracing, ties, and anchorage points.

During the inspection, the competent person will look for signs of wear and tear, corrosion, loose connections, missing components, or any other issues that could compromise the safety of the scaffold. They will also check for proper assembly, stability, and load-bearing capacity to ensure that the scaffold can support the weight of workers and equipment. Inspectors may use tools such as levels, plumb bobs, tape measures, and torque wrenches to assess the integrity of the scaffold and identify any structural weaknesses.

Common Issues Found During Scaffolding Inspections

During scaffolding inspections, inspectors often encounter common issues that can pose a safety risk if left unaddressed. Some of the most common problems found during inspections include missing or damaged components, improper assembly, inadequate bracing or support, loose connections, unstable foundations, and overloading. These issues can compromise the stability of the scaffold, leading to accidents, falls, and injuries.

Missing or damaged components such as guardrails, toe boards, or planks can create fall hazards for workers working at height. Improper assembly or inadequate bracing can result in scaffold collapse or instability, putting workers at risk of serious injury. Loose connections or unstable foundations can also compromise the integrity of the scaffold and increase the likelihood of accidents. It is crucial for inspectors to identify these issues during inspections and take prompt action to address them to prevent accidents and ensure worker safety.

Best Practices for Scaffolding Inspections

To conduct effective scaffolding inspections, construction companies should follow a set of best practices to ensure thoroughness and accuracy. Some key best practices for scaffolding inspections include:

- Designating a competent person with the necessary training and expertise to perform inspections

- Following a systematic inspection process that covers all components of the scaffold

- Using appropriate tools and equipment to assess the safety and stability of the scaffold

- Documenting inspection findings, including any issues identified and corrective actions taken

- Conducting inspections at regular intervals, such as before first use, after any modifications, and at least every seven days thereafter

- Immediately addressing any issues or deficiencies identified during inspections to prevent accidents and ensure worker safety

By following these best practices, construction companies can enhance the safety and compliance of their scaffolding systems and create a safer working environment for their employees.

Conclusion

In conclusion, scaffolding inspections are essential for ensuring site safety and compliance with regulations in construction projects. By conducting thorough and regular inspections, construction companies can identify potential hazards, prevent accidents, and protect the well-being of their workers. Inspections help to detect issues such as missing components, improper assembly, and structural weaknesses that could compromise the safety of the scaffold. By following best practices for scaffolding inspections and taking prompt action to address any issues identified, construction companies can create a safer working environment and minimize the risk of accidents and injuries. Prioritizing scaffolding inspections is not only a legal requirement but also a moral obligation to protect the lives and well-being of construction workers.