The Top 5 OSHA Violations Of 2024: Does Your Team Know?

Introduction:

Workplace safety is a top priority for any organization, and staying compliant with Occupational Safety and Health Administration (OSHA) regulations is crucial. Each year, OSHA releases a list of the most common violations found in workplaces across the country. In 2024, there were five main violations that stood out above the rest. Does your team know what these violations are and how to avoid them? In this article, we will delve into the top 5 OSHA violations of 2024 and provide insights on how to ensure your workplace remains safe and compliant.

SymbolsFailure to provide fall protection

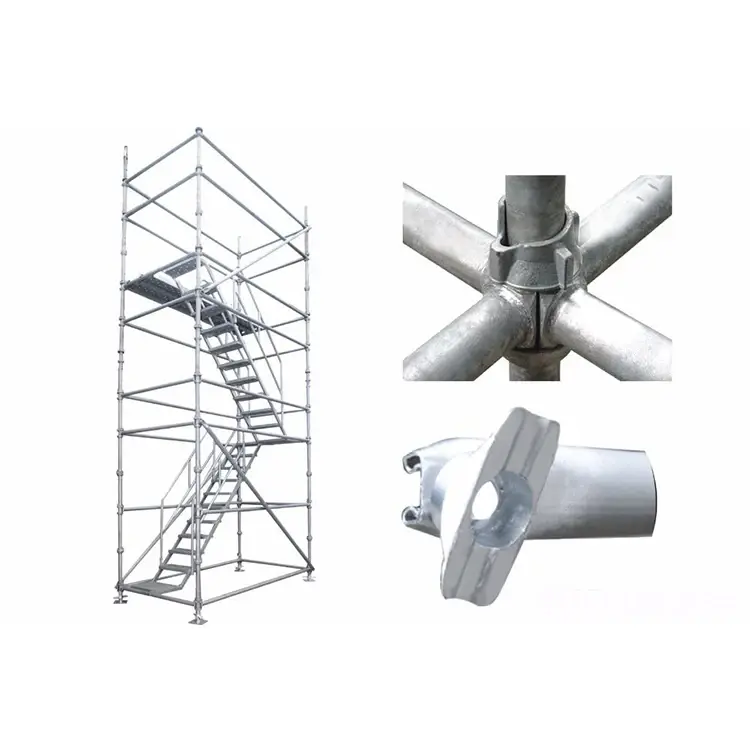

One of the most common OSHA violations in 2024 was the failure to provide adequate fall protection for employees working at heights. Falls are one of the leading causes of workplace injuries and fatalities, which is why OSHA has strict regulations in place to protect workers from this hazard. Employers are required to provide fall protection equipment such as harnesses, guardrails, and safety nets to prevent employees from falling.

To avoid this violation, employers should conduct a thorough assessment of the workplace to identify any potential fall hazards. This includes inspecting elevated work areas, such as roofs, scaffolds, and ladders, to ensure they are properly secured and equipped with the necessary fall protection devices. Additionally, employees should be trained on how to use fall protection equipment correctly and be supervised to ensure compliance with safety protocols.

SymbolsFailure to provide respiratory protection

Another common OSHA violation in 2024 was the failure to provide adequate respiratory protection for employees working in environments where they may be exposed to harmful airborne contaminants. Respiratory hazards can result in serious health issues, including respiratory diseases, lung cancer, and even death. Employers are required to assess the workplace for respiratory hazards and provide employees with appropriate respiratory protection, such as respirators and face masks.

To prevent this violation, employers should conduct air quality testing in areas where respiratory hazards may be present, such as those with dust, fumes, or chemicals. Based on the results of the air quality testing, employers should implement controls to minimize employees' exposure to respiratory hazards, such as ventilation systems and proper storage of hazardous materials. Employees should also be trained on how to use respiratory protection equipment correctly and be provided with medical evaluations to ensure they are physically capable of wearing respirators.

SymbolsFailure to control hazardous energy

The failure to control hazardous energy, also known as lockout-tagout violations, was a significant issue in 2024. Hazardous energy refers to any type of energy source that can cause injury to employees, such as electrical, mechanical, or thermal energy. OSHA's lockout-tagout standard requires employers to establish procedures for isolating energy sources and ensuring equipment is de-energized before maintenance or servicing work is performed.

To avoid this violation, employers should develop a comprehensive lockout-tagout program that includes written procedures for isolating energy sources, training for employees on how to properly lock out equipment, and periodic inspections to ensure compliance. Employees should be provided with lockout devices, such as padlocks and tags, to use when servicing equipment, and supervisors should oversee the lockout-tagout process to prevent unauthorized removal of lockout devices.

SymbolsFailure to provide adequate training

A lack of proper training for employees was another common OSHA violation in 2024. Training is essential for ensuring employees understand workplace hazards and how to effectively mitigate risks. Employers are required to provide training on a variety of safety topics, including hazard communication, emergency procedures, and the proper use of personal protective equipment.

To address this violation, employers should develop a comprehensive training program that covers all relevant safety topics and is tailored to the specific risks present in the workplace. Training should be provided to all employees, including new hires and seasoned workers, and should be conducted regularly to reinforce safety protocols. Employees should also receive refresher training as needed and be encouraged to ask questions and seek clarification on safety procedures.

SymbolsFailure to meet machine guarding requirements

The final common OSHA violation in 2024 was the failure to meet machine guarding requirements to protect employees from the hazards of operating machinery. Machine guarding is essential for preventing injuries such as amputations, fractures, and lacerations that can occur when workers come into contact with moving machine parts. OSHA's machine guarding standard outlines specific requirements for safeguarding equipment, such as barriers, enclosures, and presence-sensing devices.

To prevent this violation, employers should conduct a thorough assessment of all machinery in the workplace to identify any missing or inadequate guards. Guards should be installed on all machines with moving parts that could pose a risk to employees, and employees should be trained on the importance of machine guarding and how to use equipment safely. Regular inspections should be conducted to ensure guards remain in place and functioning correctly, and any issues should be addressed promptly.

Summary:

Ensuring workplace safety and compliance with OSHA regulations is crucial for protecting employees and avoiding costly violations. The top 5 OSHA violations of 2024 – failure to provide fall protection, respiratory protection, control hazardous energy, adequate training, and meet machine guarding requirements – highlight the importance of maintaining a safe work environment. By conducting thorough assessments, providing proper training, and implementing control measures, employers can proactively address these common violations and create a culture of safety in the workplace. Remember, staying informed and proactive is key to preventing OSHA violations and promoting a safe and healthy work environment for all employees.